My lens has fungus and/or haze, what can you do?

Fungus

Fungus is a living organism that manifests itself inside of optical systems. For fungus to form, it needs a specific environment, but once it’s established it may continue to grow even in sub-optimal conditions. Generally, the conditions need to be humid and warm for fungus to settle in. Initially, tiny spores form that are too small for the human eye to detect. As the fungus grows and spreads, it becomes more pronounced. Fungus can have different appearances within an optical system. Usually, it will begin around the outer perimeter of an element and spread towards the centre. It can have the appearance of a spider’s web, or like a miniature lightning strike across the coating.

Other times it can appear as a spec, randomly position on the elements surface or almost like a star shape. In this instance there are usually multiple points visible where you can see spots of fungus across the element. Fungus lives on the coating of the element. As the fungus becomes more established and grows, it ‘eats’ into the coating, forming a bond with the surface.

With fungus, it is difficult to predict the results when cleaning the optical unit. If the fungus is caught early enough, it can be cleaned off with no visible damage left behind. However, if the fungus has been there for some time, it can leave lasting effects. Even though it is possible to clean the fungus from the element, it can leave behind permanent damage to the coating where it has ‘eaten’ into it. In this scenario, once the element has been cleaned, it may still look like the fungus is there. However, on close inspection, you will notice that there is no more colour to the area where the fungus was, just the reflective surface of the element where the anti-reflective coating has been damaged.

Some manufacturers and service centres will outright refuse to work on any lens with known fungus. However, those that do must work under strict conditions to stop the spread of fungus. Furthermore, certain chemicals must be used to kill any spores of the fungus within the lens. Even those that will deal with fungus have their limits though. If a lens is riddled with fungus (it can almost look like cotton wool inside the lens) most will not open the lens and return it to the sender.

If the element has been damaged by the fungus, there are only a couple of options to repair this. The first would be to source a spare/replacement element in better condition. However, with vintage lenses this is easier said than done. The other option is to have the coating polished off the lens and have a modern day anti-reflective coating re-applied. This can be a costly and time-consuming process, if you’re able to find a company who can take on such a task. Furthermore, it can prove difficult to match the coating that was originally on the element.

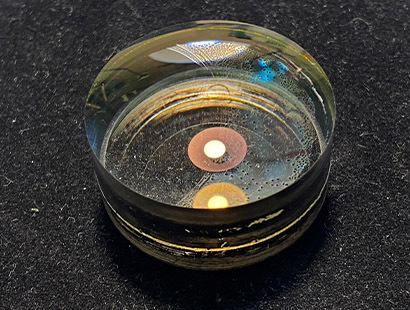

This image shows a Yashica 45mm f1.4 lens that was purchased online and sent for rehousing. On this occasion it was recommended to source another copy of the lens due to the lens being readily available and an affordable price.

It is always best to try and avoid purchasing lenses that have fungus within them, however this is not always possible. This is especially true when searching for rare vintage lenses. It is always recommended to have a professional, reputable company to assess the lens during or immediately after the purchase has been made.

Haze

Haze is often referenced when sellers are listing vintage lenses, or lenses are being assessed before having work done to them. Haze may appear like a generic term, but this is for good reason. From an external visual inspection, it is difficult to determine exactly where the haze is and what might be causing it. Haze generally refers to a ‘film’ or ‘cloudiness’ on an internal surface within the optical unit. This can be very minor or prominent, but it is always a good idea to look for this when dealing with vintage lenses. In some cases, the haze can only be seen when shining a strong light through the lens, but this could indicate potential issues for future use of the lens.

Haze can be caused by the separation of a doublet within the optical system. This is where two elements are cemented together to correct for astigmatisms and colour aberrations (read more about this here [insert link to separation and recementing article]). As the cement degrades over time, or sometimes due to high heat exposure, it can give the appearance of haze within the lens. The cement loses its optical quality and the refractive index changes. Once this process starts, it is not possible to reverse it. The best option here is to fully separate the two elements and re-cement them using modern day optical adhesive.

Another cause of haze can be the degradation of the coating of an element. As the lens ages, the anti-reflective coatings can sometimes begin to break down. This can happen uniformly across the surface, though in most cases it will be in patches as it degrades at different rates. As the coating degrades, it will change the anti-reflective qualities and appear as haze. This process is also irreversible unless going through the process of polishing and re-coating the element.

Sometimes haze can be caused by contamination within the lens. Grease/oil migration over years can spread across the surface of an element. This will give the appearance of haze within the lens. However, this is a relatively easy fix. Simply by thoroughly cleaning the element and surrounding metalwork, it will remove the haze. Furthermore, if the lens is reassembled using quality grease in the correct areas, it will prevent this from reoccurring for many years to come.

Due to the reasons described above, it is always best to have your vintage lenses assessed at a reputable service/repair centre. If any fungus/haze is suspected, the best course of action is to have the lens serviced so the extent of the defects can be determined and fed back to the customer.

If you would like to discuss this topic further or have any questions on the subject, please get in touch with us at sales@truelens.co.uk or calling our office on +44 (0)1455 848411.